What exactly is a metal laser marking machine?

In today's rapidly developing modern industrial production, metal laser marking machines have become an indispensable and important identification equipment, widely used in electronics, automobiles, hardware, medical equipment and many other fields. It is no exaggeration to say that on the big stage of industrial manufacturing, it plays a key role and gives products a unique "identity".

From the principle level, Leizhe Laser Metal Laser Marking Machine uses the high energy characteristics of the laser beam to process the metal surface. The laser generator generates a high-energy laser beam, which is precisely focused to a very small spot through a series of optical systems and acts on the surface of the metal material. The instantaneous high energy causes the local temperature of the metal surface to rise sharply, reaching the melting point or even the boiling point, and the metal material quickly melts and vaporizes, thereby achieving the desired identification effect. In this process, the energy density and irradiation time of the laser beam can be precisely controlled to ensure that the metal material in the marking area is evenly removed, presenting a clear and permanent identification, whether it is a fine pattern or a tiny text, it can accurately present it.

Why has it become the new favorite of the industry?

The reason why metal laser marking machines can stand out among many marking equipment and become the new favorite in the industrial field is inseparable from its many excellent characteristics, which make it show incomparable advantages in multiple key dimensions such as precision, efficiency, and applicability.

High precision, the king of details

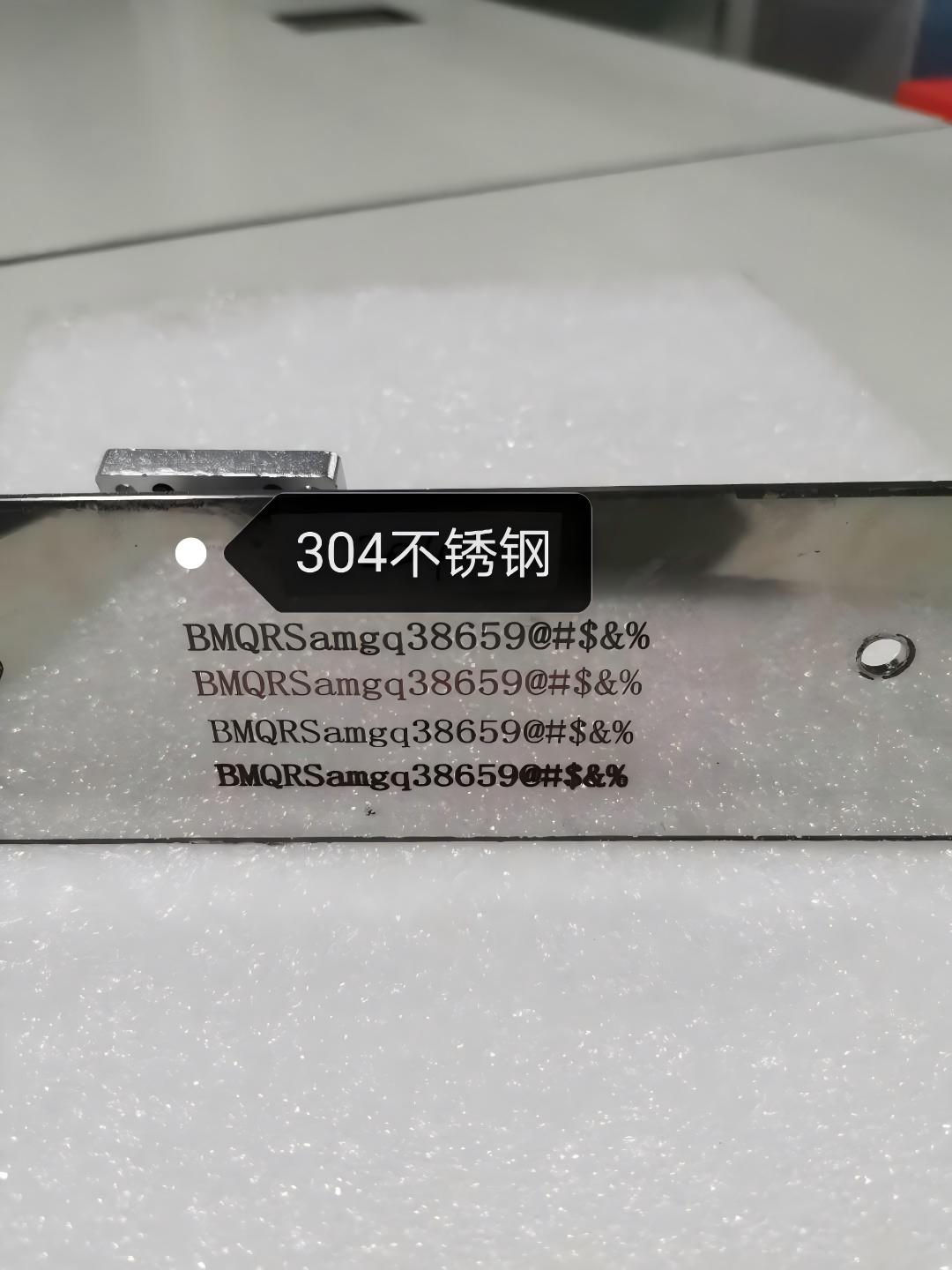

During the marking process, the metal laser marking machine can control the energy density and irradiation time of the laser beam extremely accurately. This feature makes it excellent in achieving high-precision marking effects, no matter how fine the lines are or how complex the patterns are, they can be accurately presented. In the identification scene of precision electronic components, this high-precision advantage is particularly obvious. Small electronic components such as chips, resistors, and capacitors often need to be marked with extremely fine model, specification and other information. With its high precision, metal laser marking machines can clearly and accurately complete the marking on the surface of these tiny components, ensuring the clarity and readability of the marking, and providing strong support for the production, inspection, maintenance and traceability of electronic components.

High efficiency, speed responsibility

Instant high-energy irradiation is the key to high-speed marking of metal laser marking machines. When working, the laser beam can act on the metal surface in a very short time and quickly complete the marking action. Taking the automobile manufacturing industry as an example, the production volume of automobile parts is huge and batch marking is required. Metal laser marking machines can quickly mark a large number of automobile parts, such as engine cylinders, wheels, transmission gears, etc., in a short time, marking part numbers, production dates, traceability codes and other information. Compared with traditional marking methods, its marking speed has been greatly improved, which greatly improves the work efficiency on the automobile production line and effectively shortens the production cycle.

Strong applicability, "all-round player"

The metal laser marking machine can be called an "all-round player" in the field of marking. It can be applied to the marking of various metal materials. From common stainless steel and aluminum alloys to titanium alloys and magnesium alloys with special properties, they can be easily dealt with. In the field of aerospace, titanium alloy materials are widely used due to their high strength, low density, high temperature resistance and other characteristics. Metal laser marking machines can mark high-quality marks on the surface of titanium alloy parts to meet the strict quality control and traceability requirements of aerospace products; in the manufacture of electronic products, aluminum alloy shells, copper connectors and other metal parts can also be personalized through metal laser marking machines. Marking needs, add unique logos to products.

Non-contact, gentle process

The use of non-contact marking is a significant advantage of metal laser marking machines. During the marking process, the laser beam has no direct physical contact with the surface of the metal material, avoiding scratches, wear, deformation and other damage to the metal surface caused by contact. This feature makes it widely used in products with extremely high surface quality requirements, such as the jewelry industry. When marking brand logos, models, and serial numbers on precious metal jewelry such as gold and silver, non-contact marking will not destroy the exquisite appearance of the jewelry, but also ensure the clarity and durability of the logo, improving the reliability and aesthetics of the product; in the field of medical devices, for some precision metal instruments, non-contact marking can also ensure the integrity of the instrument surface without affecting its performance and safety.

Energy saving and environmental protection, green pioneer

Today, when advocating green development, the energy-saving and environmental protection characteristics of metal laser marking machines are particularly prominent. It does not require the use of chemical reagents during operation, avoiding the pollution of the environment by chemical reagents, and also reducing the additional costs incurred by the treatment of chemical waste. Compared with traditional chemical corrosion marking, ink printing marking and other methods, metal laser marking machines consume less energy. Traditional marking methods may require a lot of electricity for heating and stirring chemical solutions, as well as drying inks, while metal laser marking machines only need to consume a small amount of electricity for the operation of the laser generator, which effectively reduces energy consumption and meets the requirements of modern industry for energy conservation and environmental protection. It is an ideal choice for industrial production to move towards green manufacturing.

These industries cannot do without it!

The application field of metal laser marking machines is extremely wide, covering almost all important aspects of modern industry, providing key support for the production and development of many industries, and becoming an important force to promote industrial progress.

Electronics industry, a precise partner

In the electronics industry, metal laser marking machines are widely used. From tiny electronic components such as resistors, capacitors, and inductors to complex integrated circuits, you can see it. On these products, metal laser marking machines will mark key information such as product model, specifications, production date, production batch, QR code, etc. Taking the integrated circuit chip on the mobile phone motherboard as an example, the laser marking machine can accurately mark the model, manufacturer and other information on the surface of the chip. This information is of great significance for the quality traceability, production management and after-sales maintenance of electronic products. At the same time, due to the high precision and non-contact characteristics of laser marking, it will not cause any physical damage to electronic components, ensuring the performance and reliability of the product, and meeting the strict requirements of the electronics industry for fine processing and high quality of products.

Automobile manufacturing, quality assurance

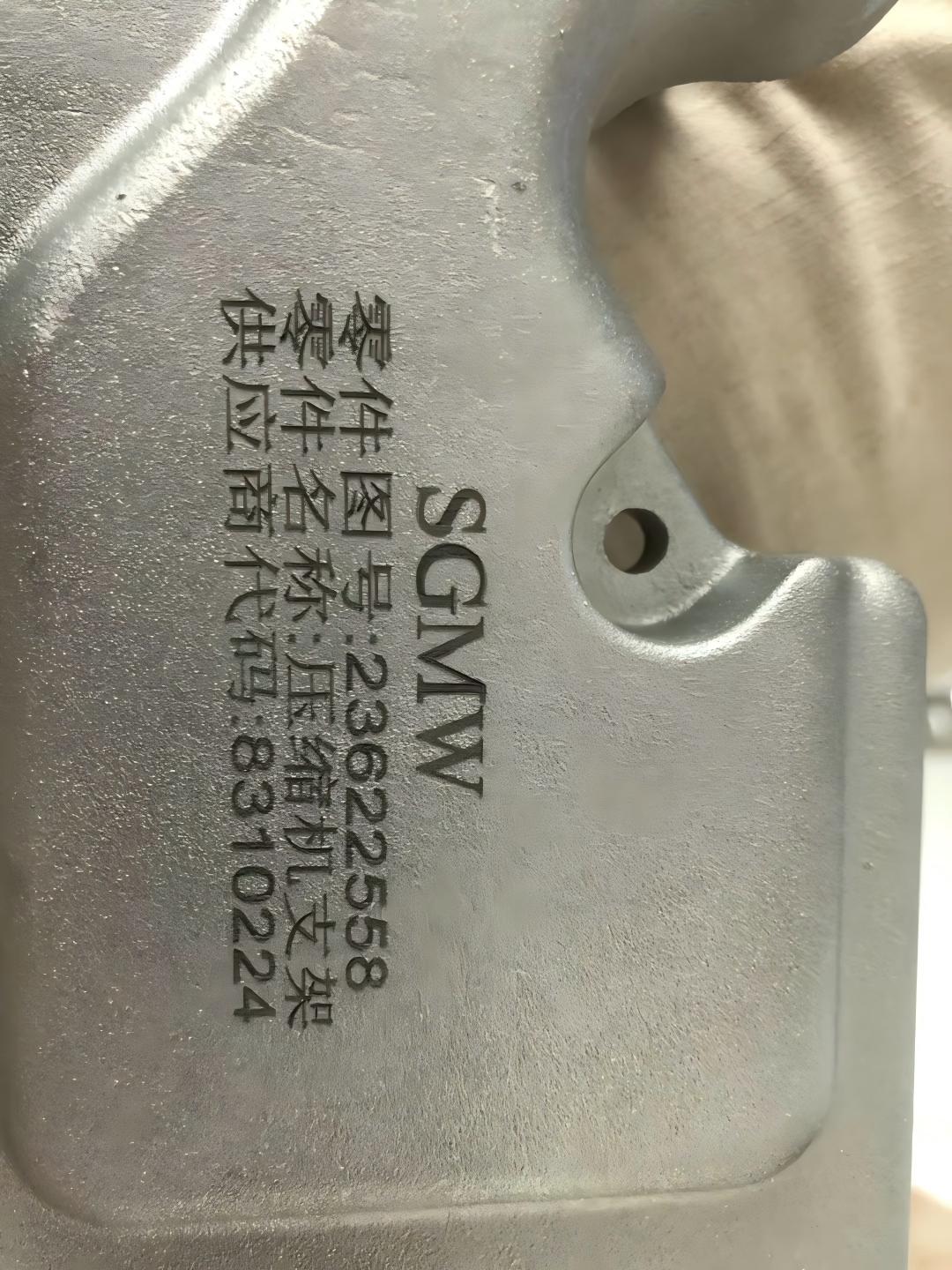

In the field of automobile manufacturing, metal laser marking machine is an important tool to ensure product quality and production management. There are many automotive parts, from key components such as engines, gearboxes, chassis, to various small screws and nuts, all need to be marked. Metal laser marking machine can mark part number, production date, batch number, traceability code and other information on these parts. For example, on the engine cylinder block, the part number and production date marked by laser marking can help to accurately manage the parts during the automobile production process and ensure that the production quality of each engine can be effectively monitored. Moreover, laser marking has the characteristics of non-contact, which will not scratch or deform the surface of auto parts, ensuring the accuracy and performance of parts and improving the overall quality and safety of the car.

Hardware products, beauty and quality coexist

Various hardware products, such as tools, locks, bathroom accessories, etc., are also inseparable from metal laser marking machines. On these products, laser marking machines can mark brand logos, product models, specifications and other information. Taking a hardware tool as an example, the laser marking machine can clearly mark the brand logo and model on the surface of the tool, which not only plays a role in brand promotion, but also facilitates user identification and selection. Due to the high precision and non-contact characteristics of laser marking, the marking lines are fine and the edges are neat, which will not cause damage to the surface of hardware products, but will improve the appearance quality and overall grade of the product, and enhance the competitiveness of the product in the market.

Medical equipment, safe protection

In the medical device industry, the application of metal laser marking machines is related to the life safety and medical quality of patients. For surgical instruments, implantable medical devices, etc., it is necessary to mark important information such as product model, specifications, production date, batch number, and expiration date. For example, on implantable medical devices such as heart stents, laser marking machines permanently engrave product information on the metal surface by high-temperature ablation. This marking method has extremely high durability and stability, and the mark is still clearly legible even after multiple disinfections and long-term use. This is very important for the quality traceability, use management, and after-sales tracking of medical devices, which helps to ensure the safe use of medical devices and reduce medical risks.

Jewelry, exquisite embellishment

In the jewelry industry, metal laser marking machines add a unique charm to jewelry. Whether it is precious metal jewelry such as gold, silver, platinum, or inlaid jewelry such as diamonds and gemstones, brand logos, models, serial numbers, purity logos and other information can be engraved by laser marking machines. For example, on the ring of a diamond ring, the laser marking machine can accurately engrave the brand logo and the 4C parameters of the diamond, which not only ensures the authenticity and traceability of the product, but also does not affect the beauty of the ring. Since laser marking is non-contact, it will not scratch or deform the surface of jewelry, and can retain the exquisite appearance and precious value of jewelry to the greatest extent, meeting consumers' demand for high quality and personalization of jewelry.

The road to the future, unlimited possibilities

Looking to the future, with the continuous advancement of science and technology, the development prospects of metal laser marking machines are bright, and they show great application potential in more fields. In the field of aerospace, with the research and development and manufacturing of new aircraft and spacecraft, the requirements for the precision and quality of parts are getting higher and higher. Metal laser marking machines will play a more important role in the identification of these ultra-precision parts. By combining with advanced automated production lines and intelligent manufacturing systems, the marking process can be fully automated and intelligent, further improving production efficiency and marking quality. At the same time, with the increasingly stringent environmental protection requirements, the energy-saving and environmentally friendly characteristics of metal laser marking machines will enable them to be more widely used in the field of green manufacturing and become an important force to promote the sustainable development of industry.

The development of science and technology will never end, and Leizhe laser marking machine will continue to innovate and progress. I believe that in the near future, it will bring more surprises and changes to our lives and industrial production with more excellent performance and wider applications. Let us look forward to the metal laser marking machine creating more brilliance in the future!